SOUNDPROOFING AND THERMAL INSULATION

Need to know:

Therefore a good sound-absorbing material usually has little soundproofing power and vice versa. The absorption by porosity (i.e. materials with open cells or semi-open cells) is generally high at medium and medium-high frequencies, while a significant damping of low frequency requires the use of high thicknesses of porous material but especially a greater specific weight of the product that can be obtained from the bonding a sound absorbing layer to a loaded mass.

POLYURETHANE FOAM

If, however, you need to prevent the escape of noise produced inside the room itself (for example from an engine compartment), an insulating product is needed, and therefore it is necessary to increase the specific weight of the polyurethane foam with a sheet (or two) of loaded rubber (mass). To get the most out of insulation, it is necessary to apply the soundproofing product to all surfaces of the room in question, including the ceiling, through precise bonding with another anchor using special fastening systems that prevent the product from detaching due to weight, temperature changes, or the loss of consistency of the product over time.

POLYESTER FIBRE AND GLASS FIBRE

The first consists of layers of thermo-bonded polyester that, unlike polyurethane foam, does not “crumble” over time, and therefore remains active and effective for much longer. The second consists of a layer of 100% glass fibre. Both are finished with an aluminium film or a glass fibre fabric and, depending on usage, can be bonded with a sheet of loaded rubber (mass) to optimise the dampening effect.

Isopav 22 with lead or loaded rubber

Auto-extinguishing in class 2 (standard) or certified in class 1.

Polyethylene density: approx. 30kg/m3

Color: grey - black

Thicknesses: 6mm – On request, a 2mm loaded rubber sheet is applied instead of the lead sheet.

Size: Rolled sheets from 100 x 300 cm

Application: Noise insulation. Suitable for medium and low frequencies.

Isopav 11 with lead or loaded rubber

Composition: A first layer of 6 mm cross-linked polyethylene foam combined to a 2 mm thick loaded rubber sheet of about 4.2kg/m2, and a third layer of open-cell polyurethane foam of variable thickness. The result is a soundproofing and anti-vibration product. The surface is protected by a black knurled film. Auto-extinguishing in class 2 (standard) or, on demand all 3 layers that compose it are used, certified separately in class 1.

Polyurethane density: approx. 30kg/m3

Color: grey – silver

Thicknesses: 23 – 28 – 33 – 38 mm. On request, 2 loaded rubber sheets are applied which increase the soundproofing power.

Size: Sheet from 100 x 150 cm

Application: Noise insulation. Suitable for medium and low frequencies.

Isopav 11

Density: approx. 30kg/m3

Color: Metal – Anthracite

Size: 20 –25 mm – On request it can be supplied with self-adhesive bottom.

Thickness: 20 –25 mm – On request it can be supplied with self-adhesive bottom.

Application: Sound absorbing.

Isoterm

Composition: Polietilene espanso reticolato flessibile. La superficie è protetta con un film metallizzato zigrinato che lo protegge da polvere e olio. Autoestinguente in classe 2 oppure a richiesta ignifugo in classe 1.

Density: approx. 30kg/m3

Color: Grey

Thicknesses: Standard on stock 6 mm (other thicknesses on request)

Size: Rolls height 100 cm - length 30 mt

Application: Thermal Insulation

The application of a lead or loaded rubber sheet may be required to increase the specific weight and obtain good acoustic insulation characteristics in addition to the thermal one.

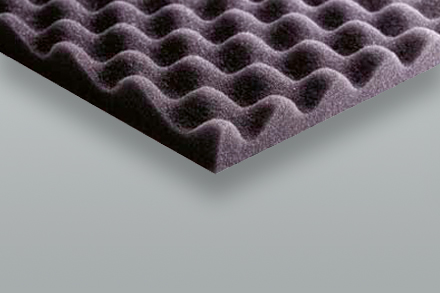

Fonox Bugnato (with an embossed profiling)

Density: approx. 30kg/m3

Color: Anthracite

Size: Sheet from 100 x 200 cm

Thickness: 35 mm / 45 mm

On request it can be supplied with self-adhesive bottom.

Application: Sound-absorbing suitable for damping high frequencies and the reverberation of sound within a room.

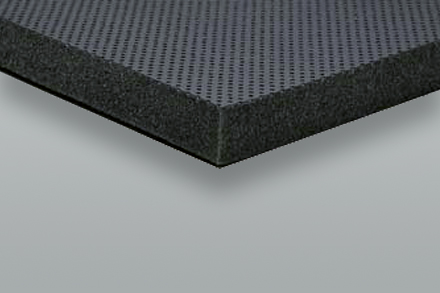

FONOX FORATO (drilled)

Composition: Self-extinguishing polyurethane foam with open cells bonded with drilled black coated fabric that protects against oil and dust.

(On demand also white and grey)

UL94 HF1 type self-extinguishing and class 2 self-extinguishing coated fabric (class 1 on request)

Density: approx. 30kg/m3 (Referred to polyester)

Color: Anthracite + coated fabric drilled

Size: Rolls height 140 cm - length from 25 to 30 mt

Thickness: 15 - 20 - 25 mm – On request it can be supplied with self-adhesive bottom.

Application: Sound absorbing.

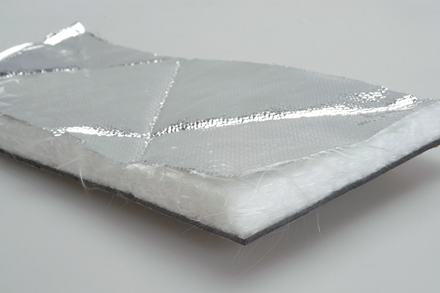

“Glassfiber” Glass fiber

GLASS FIBER THERMAL INSULATION - SOUND ABSORBING

Heat resistant up to 600 °

Quilt made of external aluminized fiberglass fabric + layer of pure glass wool with flaps + fabric in fiberglass. Excellent flexibility and resistance. Suitable as thermal insulation for high temperatures.

Size: Rolls of 100 cm x 10 meters in length

Thickness: approx. 10 cm

Weight: approx. 1,300 kg/mq

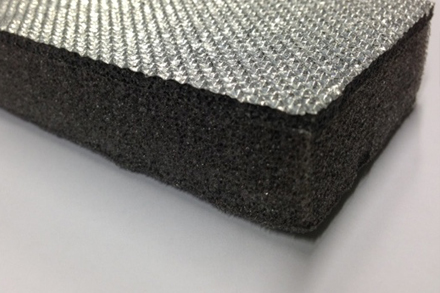

“GLASSFIBER 1 GC” GLASS FIBER WITH RUBBER

GLASS FIBER WITH LOADED RUBBER - SOUND ABSORBING.

Aluminized fiberglass fabric quilt bonded with a 2mm fireproof loaded mass layer to combine thermal insulation as well as acoustic insulation. In this case the maximum temperature that can be reached is about 150 degrees C °.

Size: Sheet from 100 x 150 cm

Thickness: approx. 12 mm

Weight: approx. 5,500 kg/mq

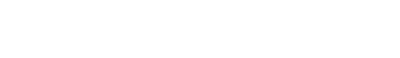

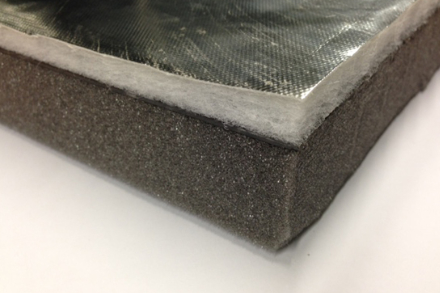

POLYESTER FIBER WITH RUBBER

POLYESTER FIBER WITH RUBBER - SOUND INSULATION.

Composition: Thermo bonded polyester flaps mattress surface finished with a metallized fiberglass fabric. This product, unlike the polyurethane foam, doesn't "crumble" over the time, therefore a longer life is obtained. To optimize the soundproofing effect, a compact rubber sheet of high specific weight is interposed to create an insulating barrier.

Size: Sheet from 100 x 150 cm

Thickness: 2 – 3 cm

Weight: approx. 4,500 kg/mq

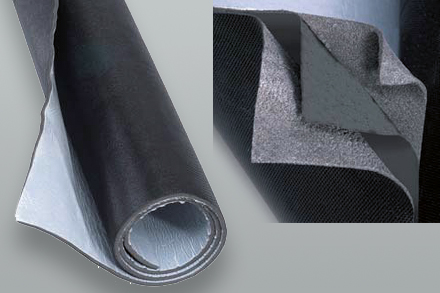

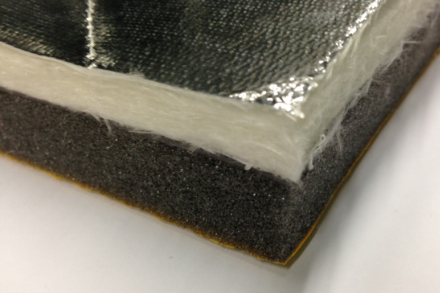

POLYESTER FIBER WITH RUBBER AND POLYURETHANE

POLYESTER FIBER WITH RUBBER AND POLYURETHANE - SOUND ABSORBING.

Composition: Thermo bonded polyester flaps mattress surface finished with a metallized fiberglass fabric to which a compact rubber sheet of high specific weight (mass) is interposed which creates an insulating acoustic barrier and finally a layer of open cell anti-vibration polyurethane foam. On demand two layers of loaded rubber (mass) can be applied to improve sound insulation.

Size: Sheet from 100 x 150 mt

Thickness: 3-4 cm

Weight: approx. 5,200 kg/mq

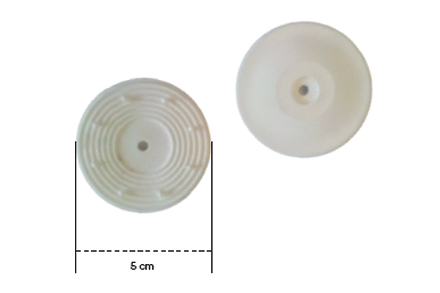

WASHERS FOR FIXING PANELS

Pack of 20 pieces.